By Kris Terauds, Economic Affairs Officer, UNCTAD

In many African countries, cotton production has languished in the two decades since liberalisation (Tschirley et al, 2009). Many factors contributed to this decline, perhaps none more fundamental than farmers deciding that other crops are more profitable to grow than cotton (Baffes, 2009). In many African countries, limited value addition constrains the prices paid to farmers: nearly all lint is exported, leaving cottonseed oil expression as the only additional source of value-added income that can be factored into producer prices. Strategies to revive cotton production must therefore increase value addition, to expand the income pool from which to remunerate farmers.

In its 2009 Regional Cotton-to-Clothing Strategy, the Common Market for Eastern and Southern Africa (COMESA) Secretariat acknowledged the need to improve incentives for farmers. Among its recommendations, it identified the development of cotton by-products as a source of new income opportunities for the sector.

With this rationale, the United Nations Conference on Trade and Development (UNCTAD) is implementing a technical assistance project on ‘Promoting cotton by-products in Eastern and Southern Africa’ in Tanzania, Uganda, Zambia and Zimbabwe. The project is funded by the United Nations Development Account and its calendar of activities runs from 2016 until the end of 2019.

The overall objective is to build countries’ capacity to evaluate and pursue new opportunities to add value to cotton by-products, derived from, for example: cotton stalks, cottonseed meal or the short-staple fibres disposed of by ginners and spinners. This is meant to contribute to increased income opportunities for farmers and entrepreneurs, especially in rural areas, and to a more resilient cotton sector overall.

Surveys Underline Raw Material Supply Challenge

Project activities began with national surveys, which gathered baseline information and stakeholders’ views on challenges facing the development of cotton by-products. Findings in all four countries identified that a limited supply of raw material was the root challenge facing cotton by-products businesses. The total quantities of some raw materials, such as linters or hulls, preclude them entirely from commercial-scale ventures. Even oil expressers — the most established value-added industry in the chain — find it difficult to turn a profit with the available quantity of raw material. This mirrors the challenge facing the textile and apparel industries, which have largely collapsed in the project countries. Although unsurprising, this finding underlines the need to address cotton production as part of any value-addition strategy, chiefly by reviving incentives for African farmers to grow cotton.

Secondary challenges identified by survey respondents included a lack of awareness about commercial applications for cotton stalks and other residues along the value chain. In particular, few farmers responding to the surveys were aware of the potential applications for their stalks. Survey respondents also highlighted trade policy as a challenge for some local products, subject to VAT, that struggle to compete with duty-free imports of, for example, edible oil and second-hand clothes.

Countries Aim to Utilise Cotton Stalks

Following the surveys, UNCTAD organized national capacity-building workshops, each gathering 50 to 80 stakeholders from the local cotton sector. The workshops led stakeholders through an evaluation of by-product opportunities, informed by presentations by the survey authors and experts from, for example, the Central Institute for Research on Cotton Technology (CIRCOT) in India, the German development agency GIZ, and the International Cotton Advisory Committee (ICAC). Stakeholders then agreed on a National Action Plan, comprised of 2 to 4 priority cotton by-products for development and supporting policy recommendations.

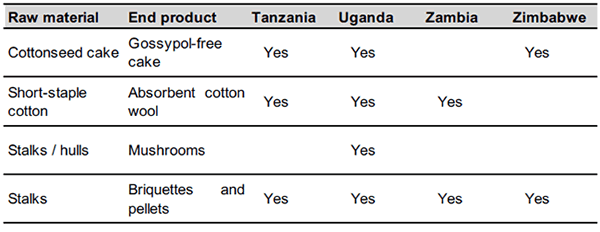

As shown in Table 1, biomass briquettes and pellets, made from cotton stalks, were the most attractive cotton by-products selected in all four countries. Several factors contributed to their appeal. They offered the greatest income potential for farmers, who can sell their stalks to processors, or even establish small- scale pelleting operations. Unlike most of the by- products discussed, stalks are relatively abundant and there is no competition for their supply. The value proposition is also compelling: they are clean fuel substitutes for firewood, charcoal, coal, liquid petroleum gas (LPG) or furnace oil.

The clean fuel advantages of biomass briquettes and pellets dominated discussions to an unexpected degree. In general, UNCTAD had framed the arguments for cotton by-products around their potential economic advantages and, indeed, increased incomes for farmers resonated. But stakeholders in all four countries quickly seized on the potential for biomass briquettes and pellets to replace more polluting fuels. Farmers saw they could replace the smoke-related health hazards of firewood in their homes. Businesses recognized the value of replacing the dust and ash associated with using charcoal or coal in their boilers. Policy makers gravitated to the potential for reducing trade deficits for imported fossil fuels. Most emphatically, stakeholders in all four countries saw biomass briquettes and pellets as a substitute for rampant deforestation, driven by growing populations over-reliant on firewood and charcoal.

Biomass Fuels Could be Competitive in Africa

UNCTAD adapted the remaining project activities to the by-products contained in the four countries’ National Action Plans. We provided advisory services to advance the commercial initiatives and policy recommendations. We also delivered practical tools, in the form of investment profiles for the selected cotton by-product processing businesses. For this, we worked in partnership with the national investment promotion agencies, which will become custodians of the profiles.

As part of the investment profiles, our consultants crafted more detailed value propositions to differentiate the profiled product from its substitutes. In the case of biomass briquettes and pellets, examples from around the world underlined that these fuels should, at a minimum, sell at a small discount to charcoal and coal and at a larger one to petroleum-based fuels, such as LPG and furnace oil.

Indeed, the USDA’s Cotton Production and Processing Research Unit, which researches commercial applications for cotton by-products, confirmed that they had explored using cotton stalks for biomass fuels, but their production costs made them unlikely to compete with the relatively low prices for fossil fuels in the USA. The price comparison was more favourable for biomass fuels in the four African project countries, where most fossil fuels are imported and relatively expensive.

Gathering Inspiration From a Study Visit to Nagpur, India

Information and expert advice only go so far; seeing technologies and businesses in operation is necessary to build entrepreneurial inspiration. UNCTAD therefore organized a study visit to Nagpur, India, where several cotton by-products have reached commercial viability over the last decade. Organised by CIRCOT, the institution responsible for research, development and commercialisation of cotton-processing technologies, the study visit aimed to demonstrate to African participants the technologies and business models that have thrived in India, as well as connect them with relevant machine fabricators. CIRCOT organised an excellent programme, including lectures by its scientists, site visits, and a forum with approximately 50 businesses active in the sector.

The cotton stalk supply chain in India was instructive for the African context. As CIRCOT expanded its research on cotton by-products in the 1990s, under then-Director Dr. A.J. Shaikh, it targeted particle boards as an application for cotton stalks (Pandey and Shaikh, 1987). Stalk- based particle boards were subsequently promoted by researchers in Africa. Nevertheless, despite years of development in India, cotton stalks proved not to be a competitive raw material for particle boards, being less abundant and more expensive than, for example, bagasse straw. CIRCOT has since focused on biomass briquetting and pelleting for cotton stalks, overseeing the growth of a budding industry over the last 5 to 10 years.

In the businesses they visited in Nagpur, several project participants saw examples that convinced them to invest in similar ventures in their countries. For example, one Indian entrepreneur had invested approximately US$200,000 for a small-scale briquetting plant with a single machine and a capacity of 7,500 metric tonnes (MT) per year. Demand for his briquettes grew faster than anticipated, meaning he was ahead of his original five-year investment payback schedule and intended to invest in a second briquetting machine. He stressed that establishing a cost-effective raw material supply chain - of cotton stalks and other agro-residues - was the make-or-break challenge for his business. Indeed, his plant was operating at approximately 5,000 MT/year, due to competition for raw material from other buyers.

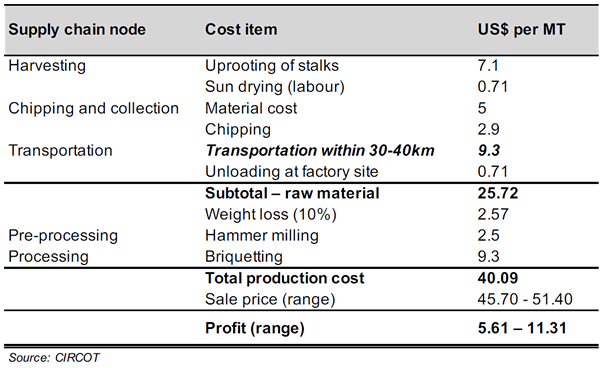

Table 2 - Estimated profit breakdown for 20 MT/day briquetting plant, India

Table 2 shows an estimated profit breakdown for a briquetting plant in India, with a capacity of 20 MT/day. It emphasises the importance of controlling raw material costs, in particular transportation.

Other elements of the briquetting plant’s business plan were less complex. The machinery was relatively simple to operate and preventative maintenance kept stoppages and repairs to a minimum. Marketing was similarly straightforward: dealers and end users in India recognised the advantages of biomass briquettes and the entrepreneur routinely sold his entire production with minimal marketing cost.

In addition to the business model, adapting the Indian examples to the African context will require several other considerations. Compressing biomass into dense fuels requires considerable force, so briquetting and pelleting machines typically require three-phase power, which is not widely available in rural areas in Africa. Participants on the study visit also remarked about the absence of ventilation systems in the Indian plants, resulting in uncomfortable and potentially hazardous air quality for workers. Nevertheless, installing ventilation systems would significantly increase the initial investment required for these plants.

More generally, the participants marvelled at the research system that supports agro-industrial development in India. The state-funded Indian Council of Agricultural Research (ICAR) is one of the largest networks of agricultural research institutions in the world and includes the Central Institute for Cotton Research (CICR) and CIRCOT. During the study visit, participants not only learned from lectures and site visits, but they were observing the fruition of approximately 30 years of CIRCOT’s work on researching and commercializing cotton by-products processing technologies, carried out in close collaboration with the private sector. Comparable examples of well-funded research institutions with long-term public-private collaboration are rare, in Africa and elsewhere.

Next Steps

For the remainder of the project, until the end of 2019, UNCTAD will assist the countries in drafting investment plans and project proposals for their selected initiatives. Country representatives will present these initiatives, as well as share lessons from the project, at a wrap-up workshop in mid-2019, to which UNCTAD will also invite donors and partners. We hope to have one or two concrete projects spring out of this first capacity-building phase.

As well as following up on its current project, UNCTAD has undertaken a joint initiative on cotton by-products with the WTO and ITC. The three ‘sister’ trade institutions proposed the initiative to respond to Member State requests, coordinate their work and capitalise on their complementary areas of expertise. WTO Members endorsed the joint initiative at the November 2018 Cotton Days proceedings.

Conclusion

Experience from UNCTAD’s project on ‘Promoting cotton by-products in Eastern and Southern Africa’ suggests there is potential to establish profitable processing businesses in Africa for selected cotton by-products, such as absorbent cotton wool and biomass briquettes and pellets. Commercially viable technologies and business models exist in India and elsewhere, representing opportunities for South-South cooperation and examples for African entrepreneurs to adapt in their countries. Generating additional income in the cotton value chain can help increase seed cotton prices paid to farmers and revive their incentives to grow more cotton.

Acknowledgements

UNCTAD is grateful for the capable coordination provided by the project’s country focal points: the Ministry of Industry, Trade and Investment in Tanzania; the Cotton Development Organisation in Uganda; the Ministry of Commerce, Trade and Industry in Zambia; and the Ministry of Industry, Commerce and Enterprise Development in Zimbabwe. Thanks also to our valued partners — the United Nations Economic Commission for Africa (UNECA), COMESA and CIRCOT — and to the motivated stakeholders and associations that have animated the project’s activities.

References

Baffes, J. 2009. The ‘Full Potential’ of Uganda’s Cotton Industry. Development Policy Review, 27: 67-85. doi:10.1111/j.1467-7679.2009.00436.x.

Pandey, S., Shaikh, A. 1987. Utilisation of cotton plant stalk for production of pulp and paper. Biological Wastes, 21:1: 63-70. doi: 10.1016/0269-7483(87)90147-9.

Tschirley, D., Poulton, C., Labaste, P. 2009. Organization and Performance of Cotton Sectors in Africa. The World Bank, Washington D.C. ISBN: 9780821377703.