Written by Antonella Teodoro and Luisa Rodriguez, Article No. 53 [UNCTAD Transport and Trade Facilitation Newsletter N°86 - Second Quarter 2020]

In the first quarter of 2020, the coronavirus pandemic led to a 3% drop in global trade values. COVID-19 could trigger the biggest economic contraction since World War II, affecting all industries from finance to hospitality.

As there is significant uncertainty about how the epidemiological and economic situation will evolve, assessing the duration and the gravity of the pandemic seems like an impossible task.

However, recent forecasts suggest: trade volumes decreasing between 13% and 32% in 2020 (WTO, 2020), global growth falling to -3% (IMF, 2020) and different maritime seaborne scenarios ranging from a return to sector average (around 3% p.a.) after 2022 to growth rates falling by 17% by 2024 (Stopford,2020)[i].

Industries whose operations are more globalized (and particularly those that rely on Chinese inputs for production) were most exposed to initial supply chain disruption due to COVID-19. This was the case for precision instruments, machinery, automotive and communication equipment (UNCTAD, 2020).

Given its non-essential nature, the fashion industry faces significant risks. Indeed, in times of COVID-19, as consumers around the world remain in lockdown, they no longer need new products. This industry is characterised by a highly integrated global supply chain.

In it, many developing countries play the role of the supplier of low-cost inputs. This article highlights some of challenges and concerns that some of these countries face, many of which are dependent on textile and garment exports.

The textile industry supply chains, trade logistics and developing countries

The accession of China to the WTO (2001) and the expiry of the WTO Agreement on Textiles and Clothing (which ended a 10-year trade regime managed through quotas) on 1st January 2005 contributed to making China an important centre of textile and clothing global value chains (GVCs).

These two developments led to shift apparel production and sourcing (by globalized retailers and producers) to China and other Asian countries because of low labour costs (UNCTAD, 2005), following the cost-reducing logic of GVCs.

As wages gradually rose in China and Chinese plants moved to produce higher-value goods, countries like Bangladesh, Pakistan and Vietnam, with lower wages costs started attracting factories to relocate their production from China.

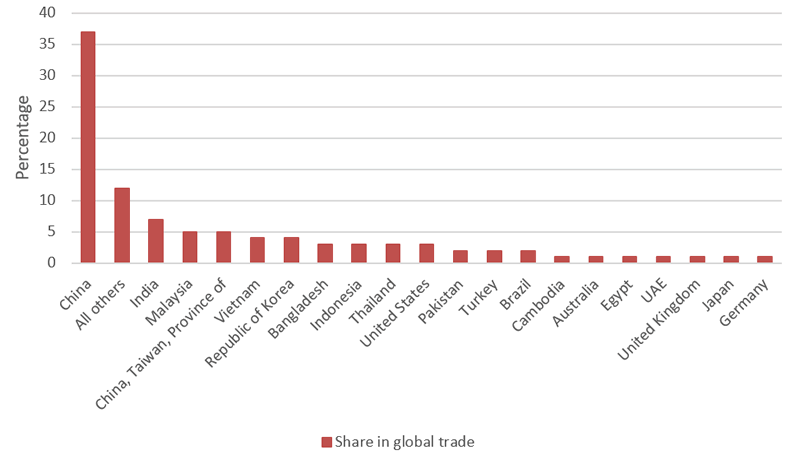

At the global level, China remains an important supplier of fashion goods (as shown in Figure 1) but has also become an important consumer of this industry.

(share in global exports), estimated TEU 2019

(Source: MDS Transmodal, March 2020)

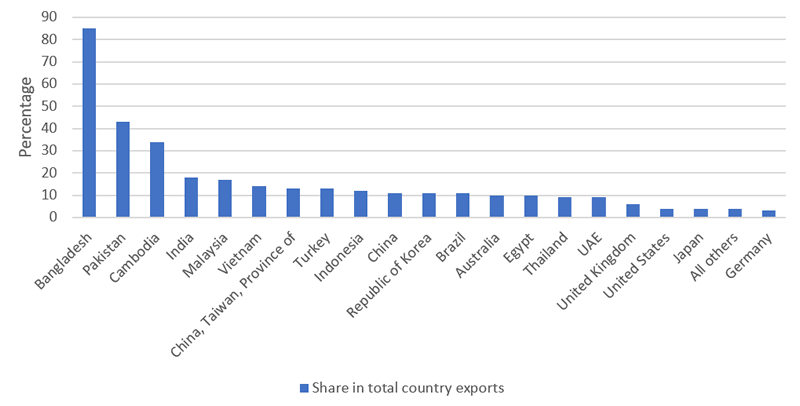

Major exporters of fashion goods for whom exports in the sector represent a significant share of export earnings are shown in Figure 2. Consequently, the Asian country most badly affected by the disease outbreak could be Bangladesh where circa 85% of its exports include fashion goods, as shown in Figure 2.

(share in total country exports), estimated TEU 2019

(Source: MDS Transmodal, March 2020)

Given the globalized nature of the industry, companies and retailers must transport their goods and raw materials across many countries. Besides China, other countries play an important role as key hubs around which trade of fashion products takes place.

This is the case for the United States (as the most important retail market), and some European countries (such as Belgium, Germany, France and UK), with ports such as Rotterdam and Antwerp featuring prominently in this trade. (CO, 2018).

From a logistics point of view, the textile, apparel and garments industry is considered a time-sensitive industry. Irregularities in making goods reach a particular place at a specified location on time can lead to reduced (or no) profits for the textile owner.

In addition, clothing collections change quickly: their lifecycle is short (as perishable products) and their commercialization is characterized by strong seasonal peaks. In this sense, textile logistics are characterized by small stocks and short delivery times.

These goods and raw materials are usually transported using a combination of land, sea, and air. Within this trade logistics context, strong multimodal interlinkages are key to ensure Just in Time delivery.

E-commerce developments have further accentuated time-related logistics requirements, such as next day delivery, as well as the capacity of handling a large volume of returns and offering the possibility for manufacturers and dealers to check the location of their articles at any time.

Emerging concerns related to COVID19 from the perspective of developing countries

Supply chain disruption: the reduced demand perspective

The COVID-19 outbreak led to production stops in China first, followed by closures of shops elsewhere around the world.

For the moment, European and American retailers, the two destination markets for this sector, are still cancelling their orders. Cancelled orders are a cause for concern in many sourcing countries.

As shippers are increasingly invoking ‘force majeure’ clauses within their contracts to halt their payments, on 8 April, the Sustainable Textile of Asian Region (STAR) Network, the body, which brings together representatives of the producing associations from Bangladesh, Cambodia, China, Myanmar, Pakistan and Vietnam, released a joint statement on the issue.

It urged brands and retailers to consider the impact that their purchasing decisions during the coronavirus pandemic could have on workers and small businesses in the supply chain and, therefore, to honour their contracts with their suppliers.

In their statement, the STAR Network invited global businesses to “support business partners in the supply chain as much as possible, and aim at a long-term strategy of business continuity, supply chain unity and social sustainability.”

Supply chain disruption: the reduced production perspective

the evolution of local epidemiologic situation in key sourcing countries, has impacted workforce availability and production, as well as multimodal logistics underpinning global value chains.

One of the concerns in this respect is that production of fashion goods could be moved away to other sourcing countries that are resuming activities faster in the Asian region or that are closer to retailers to diversify their supply chain risk.

Governments in developed countries around the world are implementing unprecedented actions to ease the effect on their economies from measures put in place to limit the spread of the pandemic.

Most developing countries do not have similar financial means, health systems or social safety nets to respond to the COVID-19 pandemic crisis and its economic impacts.

In this context, various assistance packages have been announced by IMF, the World Bank and others with a view to supporting economies, including emerging market economies.

Transport connectivity impact

Observable changes derived from the pandemic concerning maritime transport networks include, for example a reduction in service frequency (blank sailings and idle fleet) and changes in routing affecting particularly Asia-Northern Europe services, a key axis in the trade of fashion goods.

Shipping lines are reducing the number of port calls in the maritime services they offer to adapt to declining demand and cargo imbalances (JOC, 2020).

This is likely to affect the liner shipping connectivity of sourcing countries both in terms of intercontinental as well as intra-regional feeder calls and, if this situation persists, could make economic recovery even harder.

The fashion industry is undoubtedly under pressure in these uncertain times. Depending on the role that countries play in the supply chain, building resilience could entail different needs and approaches.

Prospects appear particularly bleak for low-cost sourcing countries that are highly dependent on textile and garments exports for revenues, concurrently faced with the challenge of limited financial means and less developed health systems and social safety nets to cope with the socio-economic effects of the pandemic.

In the short-term, lockdowns around the world have thrown a spotlight on risks associated with high supply chain interconnectedness and challenges associated with global sourcing.

This has also had an impact on trade logistics, as the glue that holds global value chains together. Observable changes introduced in maritime transport services to cope with reduced demand and cargo imbalances illustrate this.

The key question is what will this mean in the longer term, after surviving this unplanned humanitarian and financial crisis, particularly for the weakest links of the chain?

Driven by growing pressure towards more environmentally friendly lifestyles, the fashion industry was already confronted, before the pandemic, with increased concerns regarding its sustainability footprint, particularly consumption patterns associated with ‘fast fashion’ (increasing levels of expenditures and waste disposal) and associated production patterns (workplace conditions, environmental impact of textiles processing).

Will the current crisis accelerate a transformation in consumption patterns, inducing structural changes to the industry supply chain?

For example, could it lead to generalize new models such as ‘seasonless designs’ or lead to shorter value chains (i.e. increased local or regional sourcing)? Certainly, moving away from the “just in time” or “made- to- order” business models will have an impact on trading and transport patterns.

[i] Stopford, Martin (2020). Coronavirus, Climate Change & Smart Shipping: three maritime scenarios 2020 – 2050.

Contact:

Antonella Teodoro ¦ Senior Consultant ¦ MDS Transmodal ¦ [email protected]

Luisa Rodriguez ¦ Economic Affairs Officer ¦ UNCTAD Trade Logistics Branch ¦ [email protected]

----------------------